Throughout the years there has been an ever-increasing demand for specialty cleaning, either in conjunction with other manufacturing processes or stand-alone. The concept of "job specific" systems is not a new idea, but only a few markets can justify the development of equipment exclusively developed for it during the embryonic stage. Over time whole Industries spring up to address emerging and changing needs. One such development is the plastic container industry. The past decade has seen the plastic box either with hinged or detachable lid replace the traditional cardboard shipping box, as well as a multitude of plastic dunnage replacing wood.

Plastic containers as shown here are very rapidly becoming a "norm" in today's recycle and reuse attitude. Alternatives to wood and paper products have gone a long way in saving our natural resources. These containers are robust, impervious to water damage, and may be reused many times over and for many different applications.

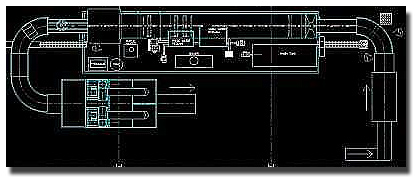

Complete Modular System Design Approach

Pioneer Industries can fully engineer your system from the ground up. We understand this varied market and

the multiples of different configurations that these bins and skids come in. Each system is different; in that it is

specifically manufactured to suit not only the various part profiles, but the plant/facility layout. Systems with 90 or even 180 deg. turns are not unusual. Pioneer Industries approaches its washing systems using a modular design. the multiples of different configurations that these bins and skids come in. Each system is different; in that it is

specifically manufactured to suit not only the various part profiles, but the plant/facility layout. Systems with 90 or even 180 deg. turns are not unusual. Pioneer Industries approaches its washing systems using a modular design.

We have several modules available such as, label strippers, blow-off systems, wash and rinse sections, dehydration tunnels and tilt-load tables.

Specialty Conveyor Systems

Specialty conveyors are standard:Pioneer suggests that systems be in a straight line. However plant layouts often dictate that a different path is required. Here a bin washing system incorporates a 90 deg. turn after the wash section. After this, the bins are conveyed to the Pioneer Cyclonic Blow-Off system and finally to a dehydration tunnel. Note the overhead and table height conveyors.

Blow-Off System Modules

This blow-off system module is installed at a busy facility washing both hinged top plastic bins and separate bin/lid combos.

This facility utilizes a dual conveyor system to carry both bins and lids through the process. The 100HP blow-off-system accommodates many different size bins and the system effectively processes over

1600 units per hour! 1600 units per hour!

Custom Designs

Pioneer Industries blow-off systems are fully adjustable and require very little maintenance and are Custom Designed From the Ground Up!!!

This layout manufactured for a retrippable container firm in Ontario shows a compact footprint and

multiple turns. Each module is shipped whole for easy field install. This system features separate label stripping and 100hp Blow-off-system sections.

Twelve different sizes of bins are processed.

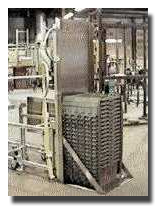

Tilt - n - Load Tables

Pioneer

Industries also manufactures specialty handling

devices such as this custom designed tilt 'n load

table. We found that the large amounts of bins were

causing a handling logistic problem to effectively

feed the wash system with a steady stream of bins. Our

solution allows operators to load the heavy stacks of

bins, and separate them at a more comfortable height

ready to slide onto the conveyor.

Here a tilt 'n load table is set at right angles to

the dual strand conveyor. Bins are brought to the

table and easily tilted to a horizontal position and

slid onto the conveyor lugs. The yellow arch is

another operator station to load lids onto the

overhead conveyor track. Pioneer also produces all

required pumping and tank systems for our units

including high volume and high pressure label

strippers.

Pioneer's tilt 'n load table makes loading product

onto the washing system a snap. The moveable unit,

shown here, is easily handled by one person. Heavy

duty handles, catches ,and a structural steel

galvanized frame make our tables built to last. Table

tops come standard in stainless steel construction.

Our tables can be made moveable or built on as part of

the entrance table. Tables are custom made for the

product being processed through the wash system.

Pioneer can also supply specialty lifting and handling

equipment for larger containers and pallets

|